I left TLC Legal in December 2019, hoping to do some exciting things in the coming times. Covid struck in March 2020.

I have been at home since March 2020.

When Covid cases dipped in the winter of 2020-21, several friends and family travelled, took vacations. Masoom and I didn’t because we had a teeny-tiny baby, so we had to be very cautious. I will try to be honest. I am on the verge of depression. I am not at all on top of things. Quite the opposite. I am desperate for some semblance of normalcy. But aren’t we all?

Gautam has certainly changed my life by leaps and bounds, but I cannot share it with anyone, except over a whatsapp video call. That’s how my baby talks to his grandparents-over whatsapp video call. That’s how he is getting to know the world.

And there is death all around. There couldn’t be a worse time.

Before this post becomes a crib fest, I will shift focus to the little light that still shines at the end of the tunnel. This epidemic will pass. We will come through. And when we do come through, I want to be prepared to meet the new life head on! Taking baby steps and doing whatever little I can should be the key to this.

In an earlier blog I had spoken of a failed attempt to make Mozzarella. Well, I tried again, and guess what! IT WORKED! These little victories can be such confidence boosters and, in the present times, these are exactly what I need to stay afloat.

I spent some time on figuring out the History, Biology and Chemistry behind cheese making. Also completed the Associate Level 1 course offered by the Academy of Cheese, UK, offered in India by Namrata Suderesan of Kase, Chennai. It’s a cheese tasting course, not a cheese making course. It was great fun. I’d recommend it to anyone who is interested.

Anyhow, I ordered myself 4 litres of cow milk from Provilac Dairy farm. As a matter of fact, I have visited the Provilac Dairy farms sometime in 2017 when I was considering a Dairy project. They take good care of their cows. This is the important bit- the milk I ordered this time was raw cow milk, instead of the pasteurized one I used last time.

Anyhow-from the little I have understood, cheese making has three basic raw material- Milk, culture and rennet. The several hundreds of cheese varieties that we hear of come from these three basic ingredients. What differs is the duration of resting, moulding, draining, maturing and so on and so forth and what have you. Lots to learn there.

One must understand that cheese was born out of a necessity to preserve the goodness of milk before it went bad. Milk primarily consists mainly of water and milk solids – viz. fats and proteins (caseins and whey proteins). Making cheese is essentially a method of preserving milk solids using the oldest techniques known to mankind- acidification (using starter culture or citric acid)followed by formation of curds (through a process of coagulation of milk solids using something called rennet), removal of water (or whey) and addition of salt. It is the coagulation-the making of curd-that makes cheese different to other forms of preservation. From there cheese can take many paths after the curd has been formed-it can be physically manipulated, flavoured, drained in moulds, or have its rind washed.

Etymologically speaking, Mozzarella finds its roots in the Italian word “Mozzare” which means to tear (mozzarella strings apart from each other). It is one of the easiest cheeses to make in the home kitchen.

I will now show you how I went about making Mozzarella in my kitchen:

The first step was to mix Citric acid to the milk to acidify the milk or to decrease its Ph level. Now I think the proper method to acidify milk is by adding starter culture, and that using citric acid is just a shortcut. But I used it anyway because using starter culture is a little more tricky (think about adding yoghurt starter culture in milk to acidify it. The bacteria in the starter culture convert the lactose in the milk to lactic acid, thereby reducing the Ph). I will try using starter culture next time. The milk is now heated to 32 deg celsius, which is the udder temperature of cow. Calves drink milk at this temperature, which is very relevant because of the step that follows-coagulation using rennet.

Rennet is a substance which was originally derived from the fourth stomach of young calves, where the process of coagulation of milk curds happened. This is exactly what we want happening to our milk. We want the milk solids come together and coagulate i.e. stick together to form a lumpy mass, the way they do in a calf’s stomach. So humans used calves’ stomachs to extract this particular enzyme called rennet which is responsible for coagulation. Animal rennet is however banned in India. We use microbial or a plant based rennet, which is pretty good for fresh cheeses, but leaves a slightly bitter after taste in mature cheeses (or so I have been told, since I haven’t made aged cheeses so far).

So when the milk reached 32 deg celsius, I added rennet and let the curds rest and coagulate for about 20 mins. To check whether the curds have set, a knife should be used to cut the curd at an angle. If there is a clear separation of whey and curd, we’re good to go.

I then cut the curds into approximately 1″ cubes which were cooked in the residual whey for about 5 mins at a temperature of 45 deg celsius. This is the catch-if you are able to set curds with good consistency, which don’t crumble when you’re cutting them, you will most likely get a good mozzarella. Otherwise you will most likely end up with something chhaina like as I did last time.

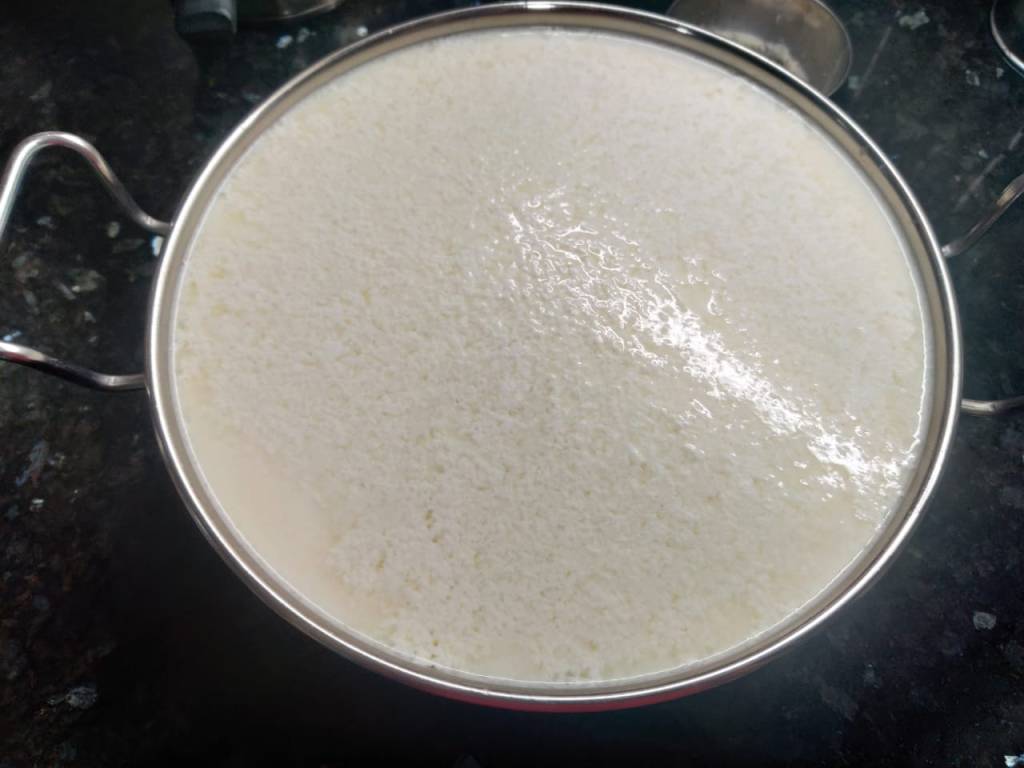

I then drained the curds in a colander for about 5-10 mins to let the excess whey drain off.

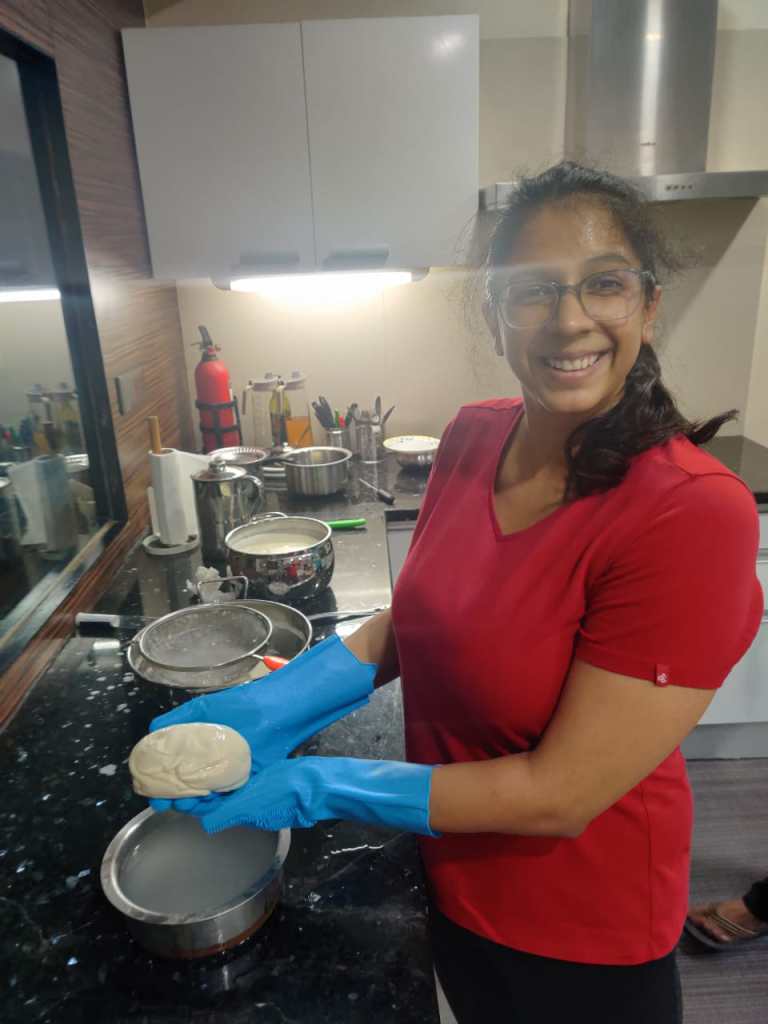

Thereafter, I moved on to the stretching of the curds, which is what lends Mozzarella its essential stringy character. Now there are two methods of stretching the curds- the microwave and the hot water method. I stretched my curds in the whey that was left over. The curds are put into hot salt water or the residual whey. This uncoils the protein in the cheese curds and turns them into long strands which are repeatedly compressed and stretched. This forces the strands to line up, creating the strings. I heated the whey to about 90 deg Celsius , added cheese salt, dipped the curds into the whey (hot, hot!) , took them out, and puuullleeedddd like so-

The stretchiness of the curds was pure joy for me. Repeated the strtching 2-3 times, rolled the mozzarella into a ball and dipped it into ice cold water.

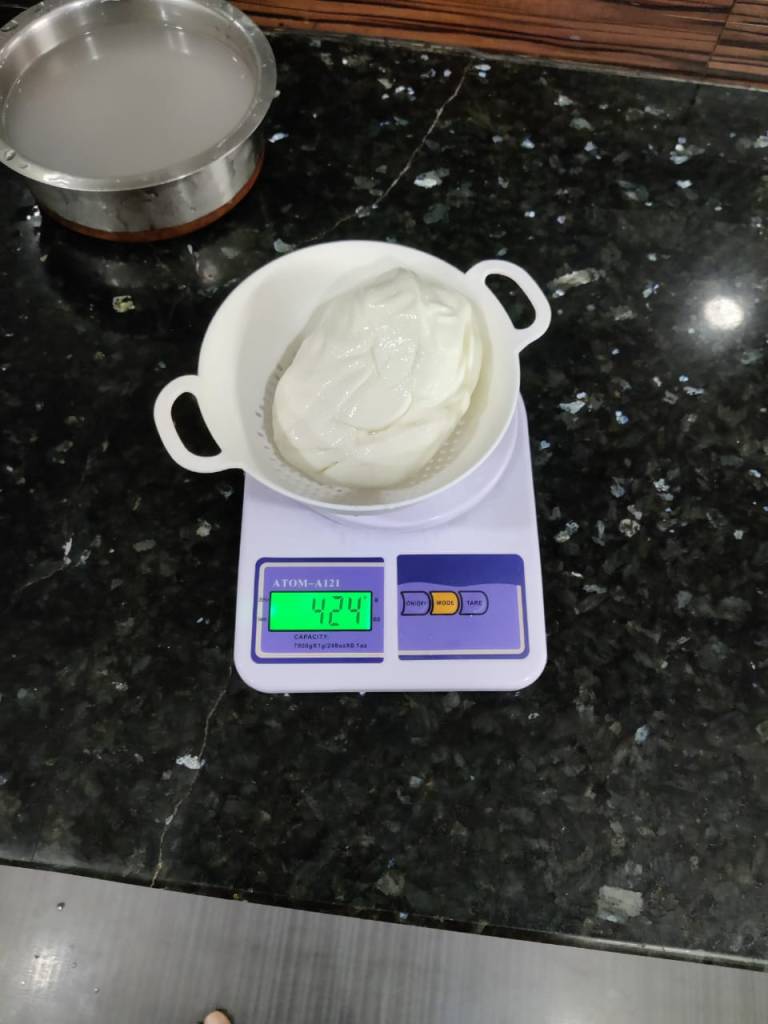

The yield was a little over 10%. I think that’s okayish.

And this is how it melted

It tasted so good! I think cheese making will have me hooked. Can’t wait to experiment with this again, and so many more. Please note that I have only recently started making cheeses. If there are any errors in my understanding and what I have written here, please feel free to correct me!